Static electricity is a common phenomenon in a print shop. Electrostatic discharges damage industrial inkjet printing equipment, affect print quality, and ignite flammable materials. Here are steps to eliminate static electricity.

What is Static Electricity

Substrate static electricity, commonly known as ESD or electrostatic discharge, is a sudden and momentary flow of electric current between two electrically charged objects. Static electricity often causes ESD through a process known as tribocharging.

When substrates contact other substrates or printing equipment and then separate, the movement of electrical potential through the air between them may produce ESD.

Sources of Static Electricity

Printing is the perfect storm for creating static electricity.

Printing is the perfect storm for creating static electricity.

ESD is caused by a lack of proper humidity control and drier conditions. Substrates from plastic to fleece are stacked in piles and dragged across each other, exchanging electrons and creating a static charge in a typical print shop. These materials moving across each other also generate heat and radiation.

Many treated substrates like plastics, including styrene, polyvinyl chloride (PVC), polycarbonate, and various types of foam boards – carry a very high level of static charge because most of these materials are treated with high-voltage corona to improve their printability.

The treatment adds a high initial charge to the substrates and increases the propensity to carry an even greater charge from lifting, sliding, rubbing, etc.

The treatment adds a high initial charge to the substrates and increases the propensity to carry an even greater charge from lifting, sliding, rubbing, etc.

In some instances, static electricity can regenerate on the substrate passing through the printer.

When these conditions combine with high humidity and moisture in the air, it becomes a perfect recipe for ESD.

Ways to Eliminate Static Electricity Around Inkjet Printers

There are solutions for controlling the static electricity in your print shop. Some printing companies use simple solutions, while others use high-tech devices explicitly made to eliminate static electricity.

Following are some of the most effective solutions.

Using an Industrial Humidification System

The first way to eliminate static electricity is by controlling the humidity in the air of your print environment. Relative humidity needs to be above 40%, and operate your printer at an ambient temperature of 20 to 32ºC (68 to 90ºF). An industrial humidifier keeps the moisture at bay.

The first way to eliminate static electricity is by controlling the humidity in the air of your print environment. Relative humidity needs to be above 40%, and operate your printer at an ambient temperature of 20 to 32ºC (68 to 90ºF). An industrial humidifier keeps the moisture at bay.

Adding moisture to the air eliminates static electricity, especially in the winter. That’s because water conducts electricity well. Potentially charged ions cling harmlessly to moisture in the air instead of your materials and equipment.

Generally, relative humidity remains at levels necessary to mitigate static electricity during summer.

We Can Help You

Contact Us

Equipment from companies like Smart Fog regulates relative humidity year-round and delivers non-wetting moisture to the air at precise levels. Temperatures of 5 to 40°C (41 to 104°F) and relative humidity of 20% to 80% will ensure optimal performance of equipment and inks.

Temperatures that are too high may degrade the ink and cause printhead clogs. Temperatures that are too low may cause the ink to freeze and damage the printheads.

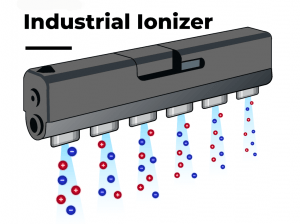

Ionizers

Ionizers

Air ionizers work by flooding the atmosphere with positive and negative ions, attracting those of the opposite polarity.

The static electricity built up on products, equipment, and surfaces are neutralized.

Using Non-Conductive Mats

Using Non-Conductive Mats

Cutting out as much conductive material through floor carpeting is essential.

Rubberized floor mats at workstations and non-conductive guards on metal surfaces can help protect equipment and individuals from static electricity.

Reduce Touch Points

Whenever two different conductive materials touch, they can create static electricity. Where there’s more activity, the current will become stronger.

Therefore, another step to reduce static shocks is to separate print production equipment and workstations by at least a few inches.

Use Static Eliminators

Certain brushes, bungees, or wands waved between plastic sheets and other substrates help eliminate static electricity. Specialized tapes and films on pallets may neutralize static electricity. Industrial air filters help reduce friction-causing dust that generates static discharges.

Fabric softeners or wipes can be used to wipe down work surfaces to eliminate static electricity, as long as it does not interfere with your substrate or other materials.

Grounding Wires

Grounding Wires

Conductive materials or objects are connected to the earth via wires, clips, cables, and clamps.

Grounding wires drain the static charges away as they are produced, removing excess charge by transferring electrons between the object and the earth.

There is no way to eliminate static electricity completely, but proper humidity control and proactive measures can make a tremendous difference when combined.

Printing Risks from Static Electricity

Apart from electric shocks to your co-worker, ESD causes severe productivity losses in the print shop under the following circumstances.

Apart from electric shocks to your co-worker, ESD causes severe productivity losses in the print shop under the following circumstances.

Substrates or Films Sticking Together

When two objects are generating a static charge, they cling together. One of the places this becomes most problematic in a print shop is with plastic sheets sent through a printer. These sheets can stick together, causing printer jams or misprints.

Dust accumulation

One of the primary concerns with static electricity is dust accumulating on the substrate and the print machine. When your substrates or films are electrically charged, they will attract dust and lint particles. A piece of lint on one substrate can cause a flaw in the print. Dust may also accumulate around the printhead, which can cause an additional risk of ESD.

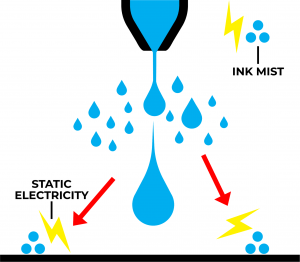

Ink manipulation

Just like static attracts dust, it can attract or repel ink. If your substrate has static electricity, ink can either be drawn to the wrong spot or fail to adhere to the proper place. When static electricity is present, it attracts the satellite mist, causing them to deviate from the intended jetting pattern. Static charge may scatter ink satellites, causing a decreased quality and blurring.

Electronics damage

Static electricity causes ink drops to stick to the printhead, eventually clogging nozzles and causing printhead damage. Static can also damage sensitive printer electronics, sensors, and controllers.

Fire

Uncontrolled static electricity risks igniting flammable cleaning solvents or ink fumes. Also, high concentrations of dust create the potential for ignition.

Kao Collins can help formulate inks that help with your environmental conditions.